Metal processing of aluminium, steel, high-strength steels and other standard materials (Cu, MS) in Olpe

Toolmaking, production and global just-in-time delivery to supply

- Sheet metal technology for automotive control systems

- Heat sinks

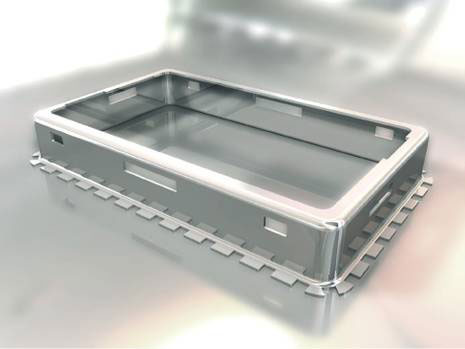

- EMC shielding

- High tensile stainless spring steel parts

- Housing components and assemblies for standard and special plugs

- Precision bending and deep-drawn parts for assemblies for rubber-metal or plastic-metal composites

- Reinforcements as a fitted part, e.g. for vibration mounts

- Sleeves and drawn parts for chassis frame components

- Axle spring plates for pivoted bogie of railway vehicles

- Stamped and bent parts and assemblies

- Brackets for automotive sensors and functional assemblies

- Handles, edge protection and fittings for wooden boxes according to DIN and TLA 004

- Special fittings

BADE UND RINSCHEID processes strip and sheet steel ranging in thickness from 0.2 to 6 mm. We have invested in special machinery that is optimised for strip aluminium processing and can handle other formats as well.

Automated stamping machines, hydraulic and eccentric presses with pressing forces of up to 3150 MPa can process strips/coils up to a width of 600 mm.

Our production complies with strict dimensional tolerances, high standards with regard to flatness and other technically demanding quality specifications, which are checked “in line” as far as possible.

Our industrial cleaning equipment is built in accordance with environmental standards and uses CHC-free organic degreaser fluids. This allows us to fulfil exceptional levels of cleanliness with regard to removal of grease residue in compliance with the latest guidelines, such as VDA 19 or DIN ISO 16232.

Manufacturing responsibly allows us to achieve the high quality standards required by our customers. Our lean organisation assures short lead times in production, a strong focus on customer demands, as well as close attention to detail.